Structure and principle of EGR valve

- 2021-12-07

- 2071

- SHANGHAI GURAN ELECTRONIC CO.,LTD

EGR system is an important technology to reduce engine nitrogen oxide emissions. It was born in 1970, earlier than the invention of ternary catalytic technology. But the technology was stalled for many years because it could not accurately control the amount of exhaust gas returned and the amount of fuel injected. It was not until the development of electronic injection technology that THE EGR system was reapplied to the engine.

EGR is short for Exhaust Gas Recirculation. In short, part of the exhaust gas generated by engine combustion is re-introduced into the intake side and re-sucked into the cylinder for secondary use. The purpose of this is to inhibit the production of nitrogen oxides (NOx) in the exhaust gas. The whole system works on the principle that the waste gas contains very little oxygen and is rich in the inert gas carbon dioxide. Once this waste gas is mixed with the fresh air that is sucked in, three effects will occur: 1. The combustion temperature will be lowered, thus inhibiting the production of nitrogen oxides; 2. Reduced heat loss of cylinder wall; 3. Fuel combustion efficiency will be improved. So from all angles, EGR system is environmentally friendly.

Role of EGR valve in system

Although the exhaust gas recirculation system has many benefits, but it is difficult to mix in the actual use of how much exhaust gas is needed to accurately control, can not exceed 15% of the fresh air, and in the engine idle or high speed, also must cut off the exhaust gas reflux, otherwise there will be the opposite effect of increasing fuel consumption. Therefore, it is necessary to have a valve that can accurately control the flow of exhaust gas. This is the EGR valve (waste gas valve).

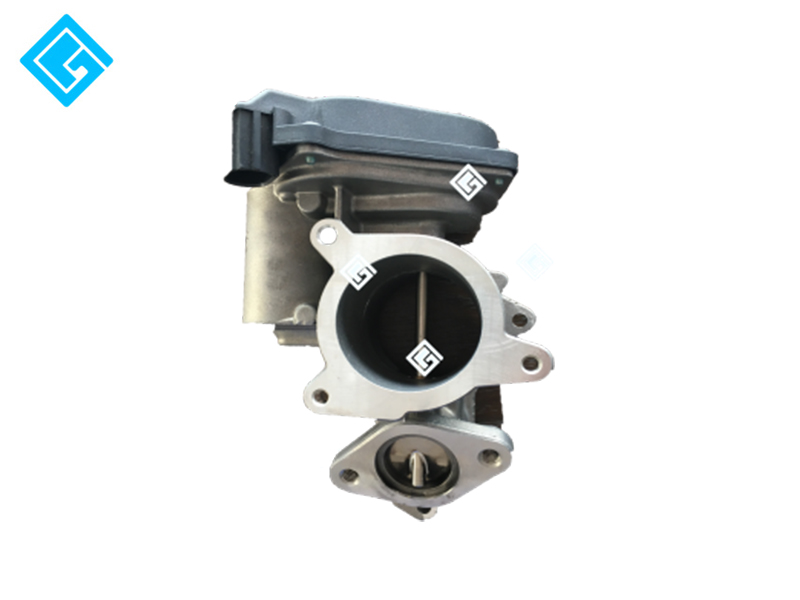

Structure and principle of EGR valve

Older EGR valves are purely mechanical and are completely governed by the laws of physics. Mechanical EGR valve is also divided into traditional and positive and back pressure type, the whole valve body like a drum, which is designed with a spring and diaphragm, through the vacuum in the intake pipe to overcome the resistance of the spring, open the valve for exhaust drainage.

However, because the physical control is not accurate enough, many of the EGR valves in high-end cars are electromagnetic, which determines the valve opening and closing is no longer the vacuum degree of the inlet, but the electromagnetic valve. The engine computer will calculate whether to open the valve and control the flow rate in real time according to the inlet air volume, inlet and exhaust manifold pressure, throttle position, water temperature, speed and other data, and then control the solenoid valve through electrical signals.

To sum up, EGR system is an effective technology to reduce automobile nitrogen oxide emissions. The principle is to introduce part of the exhaust gas into the intake side for secondary combustion. EGR valve is an important valve to control the amount of introduced exhaust gas, which is now mostly directly controlled by the engine computer.

- PREV:NONE

- NEXT:NONE

HOME

HOME PRODUCTS

PRODUCTS NEWS

NEWS CALL

CALL